Lightweight Design

Introduction

The topic lightweight design develops innovative solutions for customized and resource-efficient lightweight constructions for mobility systems and transport infrastructure. The demand for lower energy consumption and reduced CO2 emissions means that the need for innovative lightweight solutions is high.

Lighter constructions offer the possibility for an eco-friendlier mobility. In terms of transport infrastructure lighter constructions are also more resource-efficient. Further potential for lightweight designs arises from the hybridization of material systems, which allows new profiles of properties, that are not achievable with mono-material solutions.

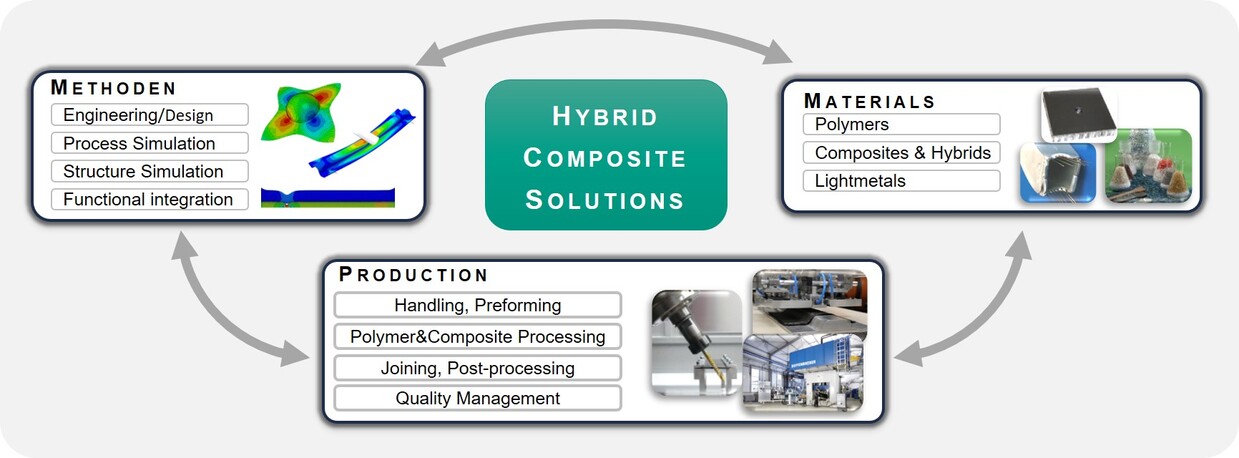

Lightweight design imposes complex requirements on shape finding. Hence, it is a complex optimization problem, which needs to consider many boundary conditions of different areas, especially in the context of increasing hybridization. In order to solve this optimization problem, competencies of the areas of methods, materials and production are needed (MMP-Approach).

The Topic Lightweight Design combines the KIT’s competencies in the areas of methods, material and production and applies them holistically to develop customised, resource-efficient lightweight products for vehicles and transport infrastructure. In the course of this, the potential of hybrid lightweight structures is researched and extended purposefully.

Research Focus

Figure 2: From fundamental research on material level [1] with the help of experimental validation [2] to the development of innovative lightweight solutions for the next vehicle generation [3].

[1] Picture provided by Tarkes Pallicity (IRTG PostDoc Project), www.grk2078.kit.edu

[2] Böhlke, T., Henning, F., Hrymak, A. N., Kärger, L., Weidenmann, K., Wood, J. T. (Hrsg.):

Continuous-Discontinuous Fiber-Reinforced Polymers. An Integrated Engineering Approach. Hanser Fachbuchverlag (2019).

[3] Deinzer, G., Kothmann, M. H. (Hrsg.): Systemintegrativer Multi-Material-Leichtbau für die Elektromobilität. Schlussbericht des BMBF-Verbundprojektes SMiLE (ISBN 978-3-8440-6638-8), Reihe Berichte aus der Werkstofftechnik, Shaker Verlag (2020).

Integration of the system lightweight design into the development process of new mobility systems

The development of lightweight products must also be controlled and supported across components. Therefore, new methods and processes for the design of complex systems are developed and existing approaches are adapted to apply them on the level of the overall system. Thus, lightweight design solutions at the interfaces to the application-specific technology-topics (Powertrain Systems, Chassis & Suspension and Vehicle Concepts) can be integrated into the overall development process of new generations of mobility systems at an early stage.

Simulation, optimization and design methods that support the entire product development process of lightweight systems

In order to develop optimal lightweight design systems on every design level, methods relating to the whole product development process are explored. As early as in the concept phase, processual and structural optimization methods of the lightweight-oriented design of overall systems and multi-material designs are employed und extended purposefully. The particular stages of production, as well as the resulting behavior of the component are depicted virtually. Consistent CAE-chains serve the virtual coupling between design, manufacture and validation.

Development and research of lightweight material

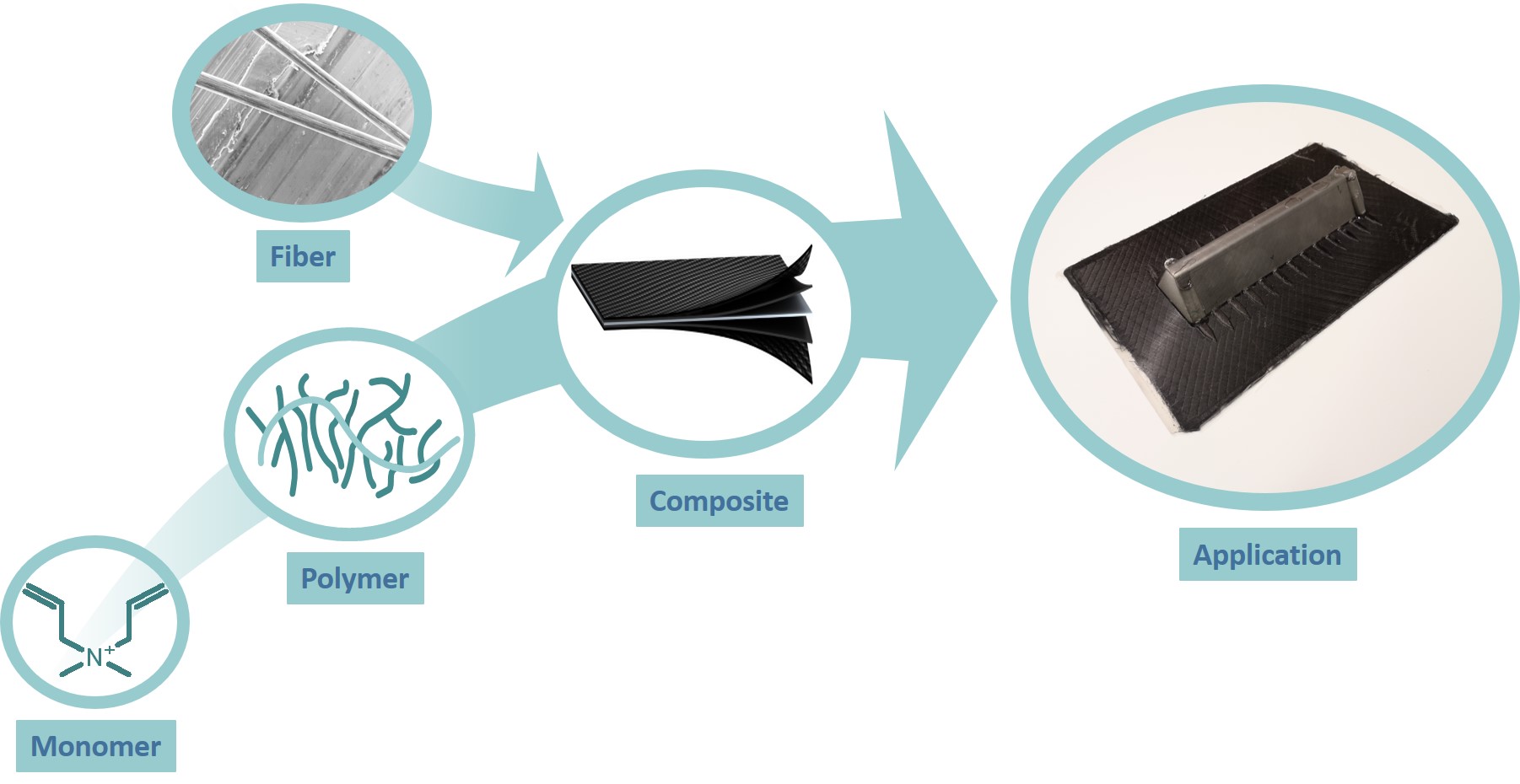

The development of modern, customized composite material is based on the basic cross-scale knowledge about its chemical composition and its physical structure, from monomer to component. Especially the molecular structure, the interface development, and possible production-related defects determine the physical properties of a compound – conversely, the knowledge of these facts allow the customization of the material properties.

Sustainable production technologies and systems for multi-material lightweight structures

In the light of a sustainable production, the fabrication of lightweight structures requires innovative production technologies and systems. High volume production plants as well as agile production systems, that can adjust to volatile quantities and component variants flexibly and quickly, are needed. The focus lies on the production of fibre-reinforced plastic with duromers and thermoplastic matrices, as well as the integration of mechanic and electronic functional components in the multi-material design.

Circularity of lightweight design – sustainability and life cycle

Lightweight design offers great potential for the reduction of moving masses and the respective energy expenditure. To use the sustainability potential of lightweight construction material, especially composite material and hybrid material compounds, in the future, their circulation must be explored and optimized. The circularity includes a recycling-friendly design and a material-efficient production, as well as the possibility to reuse, repair or remanufacturing.

Validation and monitoring of lightweight design structures

A continuous monitoring of the total life cycle of the products and an early and process-accompanying validation is increasingly important for a sustainable and successful lightweight construction. At the Topic Lightweight Design we are researching experimental and virtual validation methods for a validated and consistent digitalization of the whole life cycle (digital twin). Digital twins and AI-based methods allow us to use the collected monitoring-data for quick and effective assessments of processes and components.

Figure 3: Multi-scale analysis of lightweight materials [KIT ITCP, KIT IAM-WK].

Figure 4: Additively manufactured lightweight construction structures made of continous fibre-reinforced polymers [KIT IHM].

Associated Institutes

FAST - Institute of Vehicle Systems Technologies

IAM-WK - Institute for Applied Materials - Materials Science and Engineering

IFM - Institute of Mechanics

IHM - Institute for Pulsed Power and Microwave Technology

IKFT - Institute of Catalysis Research und Technology

IPEK - Institute of Product Engineering

ITCP - Institute for Chemical Technology and Polymer Chemistry

ITM - Institute of Engineering Mechanics

Interfaces

-

International Research Training Group GRK 2078 (Speaker Prof. Dr.-Ing. T. Böhlke, Co-Speaker Prof. Dr.-Ing. F. Henning): "Integrated engineering of continuous-discontinuous long fiber reinforced polymer structures" (CoDiCoFRP)

-

to other KIT Centers, in particular

-

to other Topics within KIT Mobility Systems Center