-

to other Topics within KIT Mobility Systems Center

-

to other KIT Centers, in particular

Production Systems

Introduction

The increasing complexity and diversity of variants due to individualization as well as the resulting low quantities lead to major challenges in process and production design in combination with volatile markets and legislation. In addition, new manufacturing and process technologies must be developed to enable a successful transition to sustainable mobility. In the research area production systems and technologies, the institutes are working across disciplines to develop novel solutions for production engineering issues in the context of future mobility. The topic production is considered holistically, from manufacturing and process development under laboratory conditions to industrial, fully automated production systems.

The research and development of agile production systems represents an important step towards the economic integration of future mobility solutions into the energy transition. Against the background of volatile framework conditions, adaptable production systems are capable of adapting autonomously and dynamically to changing product specifications, technologies and variable quantities. A key factor is the use of artificial intelligence (AI) methods for accelerated ramp-up and assistance in parameter-intensive planning as well as production processes involving existing domain knowledge. The research also focuses on the development of appropriate in-process measurement technology for manufacturing, process and production engineering. An essential aspect is the increase of sustainability in process technologies and production systems. In the context of circular economy, the topics recycling and remanufacturing are intensively researched from a production engineering point of view.

Research Focus

Electric Traction Motors

Electric traction motors represent a key component in the powertrain of hybrid and all-electric mobility solutions. Therefore, technologies and processes for economical and agile production, intelligent methods of process optimization as well as approaches for holistic optimization of product and production technology are being researched in interdisciplinary projects.

Energy Storage Systems

The production of novel energy storage systems also beyond lithium is researched in close exchange with the KIT Energy Center. The focus is on novel agile production systems for the flexible production of battery cells in terms of format, material and number of units. Furthermore, new processes are developed for this purpose.

Hydrogen technologies

Fuel cells and their peripherals for future hydrogen mobility pose new challenges for manufacturing and process technologies as well as production systems. Here, analogous to the energy storage systems, the focus is on researching and developing agile and reconfigurable production systems for the manufacturing of components for hydrogen vehicles in close cooperation with the KIT Energy Center.

Electronic/microsystems components

Efficient converters of electrical machines, DC/DC converters in the context of the energy storage system as well as power electronic components of the charging infrastructure are important enablers of electrified mobility solutions. In joint work, technologies and processes for the production of electronic and microsystem assemblies are being researched holistically.

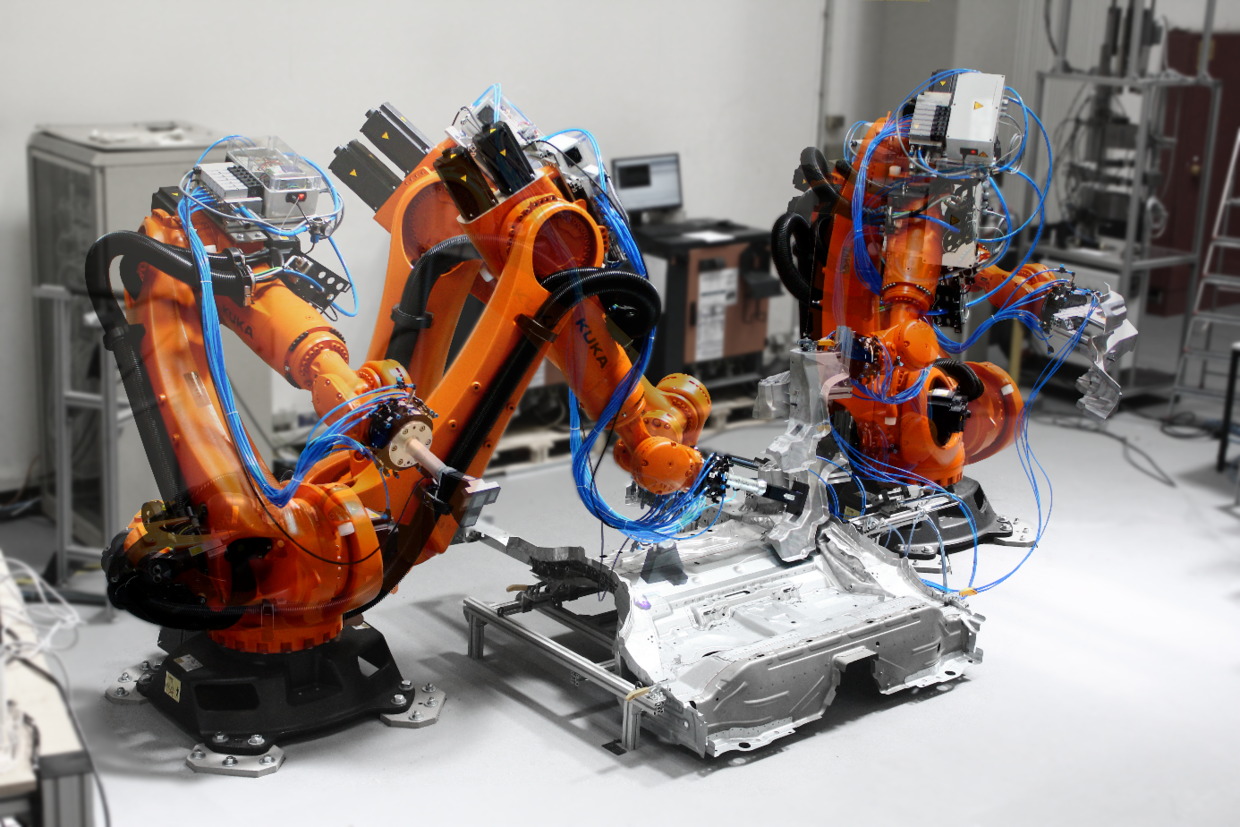

Lightweight vehicle structures

The manufacturing of lightweight components for future mobility solutions poses major challenges for production, particularly in the context of multi-material design. The focus is on agile production systems as well as technologies for processing fiber-reinforced plastics, metals and hybrids that are capable of large-scale production.

Circular economy and product data cycles

To increase the sustainability of mobility products, reuse, remanufacturing and recycling are important instruments for circular economy. Research is focused on developing automated production systems that can adapt to uncertain product conditions. In addition, research on product data cycles is gaining in importance, because product information must be made traceable and transparent from raw material to use.

Associated Institutes

ETI-HEV - Institute of Electrical Engineering - Hybrid Electric Vehicles

FAST - Institute of Vehicle Systems Technologies

IFL - Institute for Materials Handling and Logistics

IHE - Institute of Radio Frequency Engineering and Electronics

IIIT - Institute of Industrial Information Technology

IPE - Institute for Data Processing and Electronics

ITAS - Institute for Technology Assessment and Systems Analysis

MVM - Institute for Mechanical Process Engineering and Mechanics

TFT - Thin Film Technology